Versatile, flexible & efficient

We offer comprehensive services in the fields of welding, mechanical manufacturing and plant engineering for a wide range of industries. With state-of-the-art technology and experienced specialists, we carry out welding work precisely and reliably. Our mechanical manufacturing delivers customised components that meet the highest quality standards. In assembly and plant engineering, we develop and implement complex solutions that are precisely tailored to our customers' requirements. Whether in mechanical engineering, the automotive industry or the energy sector, we stand for efficiency, precision and flexibility in every phase of the project.

Welding

L&R Montagetechnik is broadly positioned in welding technology. We manufacture everything from welded constructions with unit weights of up to 8 tons to filigree components; also in series production.

Our company meets the welding quality requirements according to DIN EN ISO 3834-2 as well as EN 1090-2 and EN 1090-3 "Welding of load-bearing steel and aluminum structures". We are also particularly pleased to have been awarded certification level CL1 in accordance with DIN EN 15085-2 "Welding of rail vehicle and vehicle parts". This certification also allows us to offer our services in the field of "New construction of rail vehicles and their components".

We process a wide variety of weldable metals at 8 variably equipped manual welding stations, ranging from steels of different grades to stainless steels and aluminum. Automated manufacturing processes are used for the economical production of higher quantities. A total of 9 robot welding cells from the manufacturers ABB, Kuka and IGM with various rotary tilting tables are available, which are already used for the production of small series.

Welding supervision is carried out by a welding engineer and certified welding specialists. In addition, all employed welders have passed an examination in accordance with DIN EN ISO 9606-1 and repeat this regularly. Furthermore, some welders are certified in accordance with DIN EN ISO 9606-2 and are therefore approved for welding aluminum. A non-destructive weld seam test can be carried out on site in accordance with DIN EN 473 using the magnetic particle penetrant method.

Mechanical production

When it comes to mechanical processing, we concentrate on CNC milling. We process a wide variety of materials, from technical plastics and non-ferrous metals to tool steels. Whether a welded assembly or a contour component milled "from the solid", we can meet all requirements thanks to our versatile machinery.

Thanks to a modern CAD-CAM link to external programming stations, we are also able to manufacture workpieces with complex contours economically.

With the help of sophisticated clamping systems and in-house fixture construction, we have managed to minimize set-up times and also process smaller batch sizes economically. This enables us to react quickly to our customers' changing order situations.

When selecting our machines, we always pay attention to the greatest possible flexibility. This means that many machines can be set up in parallel to production time, as well as processing large-volume individual parts.

The Hüller Hille horizontal machining centers are equipped with pallet changers and standardized clamping cubes, making them ideal for series production as well as heavy-duty machining.

Maschinentyp | Achsen | Verfahrwege x | Verfahrwege y | Verfahrwege Z | Werkzeugplätze | Arbeitsbereiche |

DMF 360 linear | 5 | 3660 | 920 | 820 | 30 | 2-Pendeltisch |

DMF 260 | 5 | 2600 | 700 | 700 | 60 | 2-Pendeltisch |

Chiron FZ 22 | 3 | 2200 | 520 | 425 | 40 | 2-Pendeltisch |

Chiron FZ 18L | 4 | 2000 | 400 | 425 | 20 | 2-Pendeltisch |

Chiron FZ 18S | 4 | 550 | 400 | 425 | 20 | 1 |

matec 30L | 4 | 3000 | 800 | 800 | 30 | 2-facher Pendelbetrieb |

matec 30HV | 5 | 3000 | 800 | 1100 | 48 | 2-facher Pendelbetrieb |

Heller FP 8000 | 5 | 1400 | 1000 | 1250 | 100 | 2-facher Plattenwechsel |

Hüller Hille nb-h 230 | 4 | 1200 | 1000 | 1200 | 96 | 2-facher Plattenwechsel |

Hüller Hille nb-h 230 | 4 | 1200 | 1000 | 1200 | 200 | 6-facher Plattenwechsel |

Hüller Hille nb-h 290 | 4 | 1400 | 1000 | 1200 | 150 | 4-facher Palettenpool |

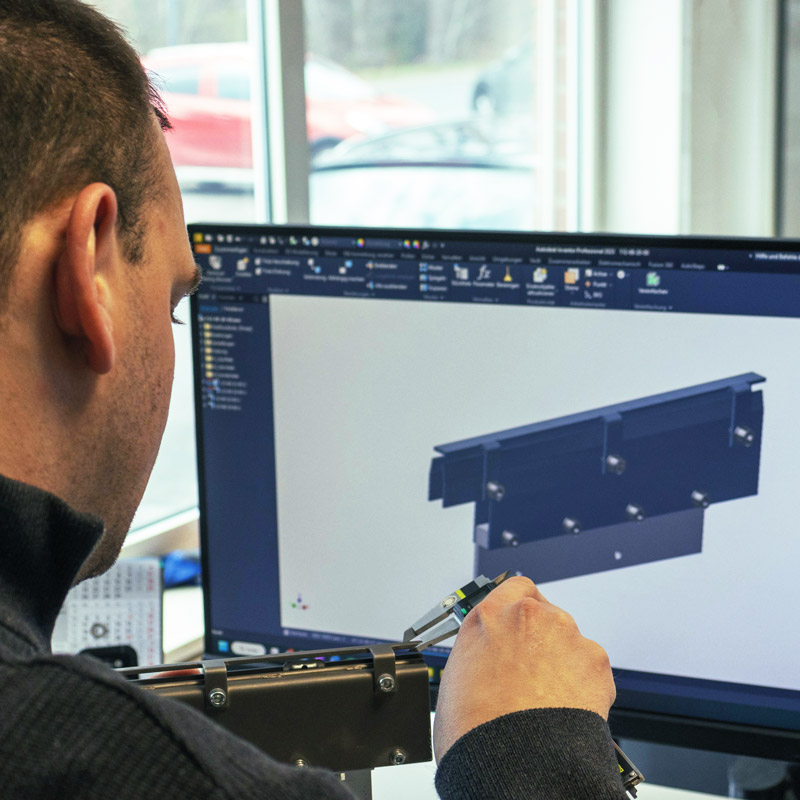

Plant construction & assembly

In special machine and plant construction, we combine our expertise and manufacture production facilities that are individually designed for our customers' manufacturing processes. It is important to us to offer everything from a single source, from design, construction and production through to commissioning.

From robot grippers to devices for machine tools and welding cells to automated conveying and processing equipment, we cover a broad portfolio of solutions for a wide range of industries.

All systems are pre-assembled and tested in our halls. On request, we are also happy to install the systems at their destination, take care of commissioning and accompany the production start-up.

One project - one contact person.